This morning I was watching Joel Telling’s new channel trailer for the 3D Printing Nerd channel and suddenly I was surprised to be looking at myself! Check out his trailing. I come in around 2 minutes and 46 seconds.

Printed Solid Grand Opening!

A freaking wonderful, invigorating event. Joel Telling’s overview of the event can be found at https://www.youtube.com/watch?v=qnZqMnokjpw

What does TGAW stand for? That is answered in Joel’s interview with me:

https://www.youtube.com/watch?v=REvIWbER_Gc

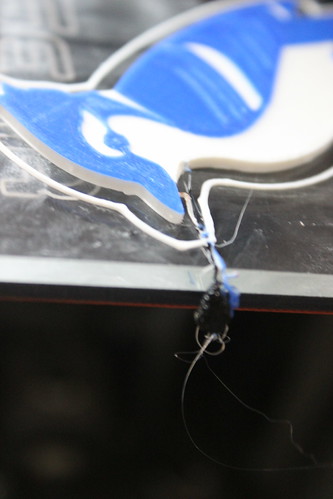

Anglerfish

Blog post with more details on the creation of my bronzeFill/GlowFill Anglerfish. I do have one more if you happen to covet one. 😉

http://tgaw.com/wp/?p=307

Bow Ties!

I’ll work on a video about their design in Blender and the attachment design in OpenSCAD. It’ll use words like “Texture”, “Baking”, “Displacement Maps” and “Boolean Intersection”. In the meantime, I do have some listed on Etsy at https://www.etsy.com/shop/VickyTGAW

Land’s End Gazebo

The real live gazebo in Sayville, NY can be found here http://www.landsendweddings.com/

Geocoin

Check out the AMAZING family I am designing for. You couldn’t get better inspiration than that!

https://www.youtube.com/watch?v=znnSSlJF79w

Make Your Empty Filament Spools into a Shelf

As promised, the model is up on Thingiverse as well as the original OpenSCAD code.

http://www.thingiverse.com/thing:1677024

Print in Place Gyro Cube!

Wanna beta test my version of the Gyro Cube on YOUR printer? Lemme know!

Thanks for watching! Happy Printing!