I butted into a conversation in Twitter today (That’s socially acceptable right? I hear it’s the cocktail party of the Internet) and the question came up how to get the Maker Gear M2 to run some filament before the print.

Well, since I do a lot of material changes within prints, that is something I do know how to do.

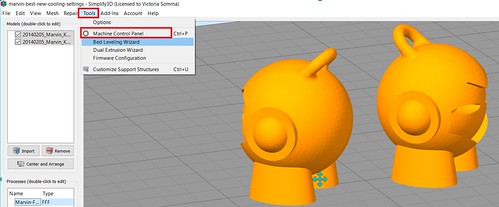

Simplify3D – Jog Controls

You can tell your printer to do all sorts of things in the Machine Control Panel section of Simplify3D. For that, you would:

- Click on Tools->Machine Control Panel.

- And then you can go to the Jog Controls Tab.

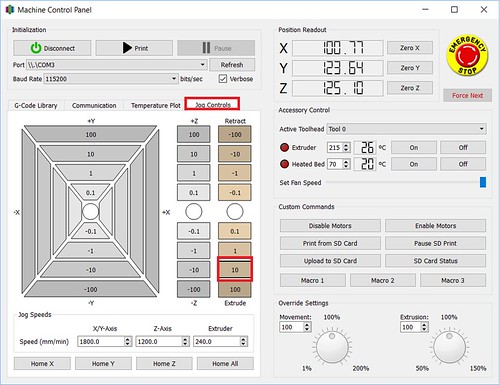

- There is an Extrude section, where you can tell the printer to extrude out 0.1mm (tiny, tiny!), 1mm, 10mm, 100mm. I am typically using the 10 or the 100 button.

Tip: If you already have a print on the bed, I put a piece of paper over it so it doesn’t get messed up with the extruded filament.

Gotcha: The printer has some built in safeguards– it won’t do a “Cold Extrude”. It won’t extrude unless the nozzle is heated up. If you are hitting those Extrude buttons and the printer is not listening to you, it may be that it isn’t heated up yet. (The G-Code command M302 supposedly turns off the Cold Extrude safeguard, but I have never tried it)

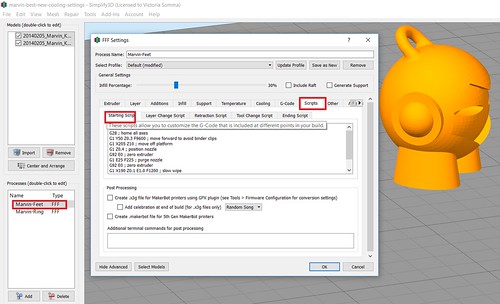

Simplify3D – Custom Starting Script G-Code

Simplify3D allows you to set up custom code for various stages of your print, including the start up. To edit those, you would:

- Double click on your setting profile in the bottom left hand corner

- Click on the Scripts tab

- Click on the Starting Script tab

For all my simple prints, I use the stock Starting Scripts that came with the Simplify3D Default Profile for the MakerGear M2 (24V vb3 Hot End) (I do customizations for my multistep prints)

M108 S255 ; turn on M2 fans G28 ; home all axes G1 Y50 Z0.3 F9600 ; move forward to avoid binder clips G1 X205 Z10 ; move off platform G1 Z0.4 ; position nozzle G92 E0 ; zero extruder G1 E25 F225 ; purge nozzle G92 E0 ; zero extruder G1 X190 Z0.1 E1.0 F1200 ; slow wipe G1 X180 Z0.25 ; lift

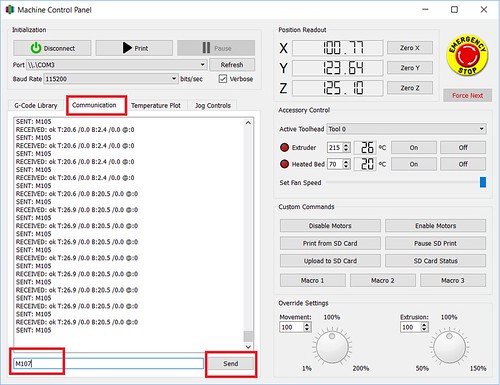

Simplify3D -G-Code Via Communication Tab

Want to be a little more hard code than the Machine Control Panel tab, but don’t want to commit to a change to your Starting Script? You can also send direct G-Code commands to your printer by:

- Going to Tools->Machine Control Panel

- Clicking on the Communication tab

- Typing stuff in the text box in the bottom and hit Send.

Tip: A good reference for G-Code syntax is at: http://reprap.org/wiki/G-code

Gotcha: The commands are CASE sensitive. m107, for example will not turn off my cooling fan, but M107 will. : )

Both prints have these filament morgellons sticking out of them. Close observation during the print reveals that a little bit of filament continues to seep out of the nozzle as the machine switches colors. That tuft of filament catches on the print the next time the extruder sweeps over the top layer. Maybe this could be fixed in gCode by running the extruder drive motors in reverse for a bit in-between colors. I dunno.

or maybe running GCode to do a swipe along the side of the glass would help get rid of that blob.

I have been known to take a pair of plyers and snag excess filament off my nozzle as a print starts as well. 🙂