Phew. A whole SLEW of updates for you. Been quite busy.

Printer Problems

In high school, when I would meet friends for rollerskating, I would always be tense about falling. It just seemed like the worse thing that can happen. But after that very first fall each skating adventure, I’d relax. It was never nearly as bad as I thought.

So it goes with issues with the MakerGear M2. We had a slew of issues crop up recently. But so far (knock on wood), none of them were as paralyzingly scary as I envisioned printer problems to be. And holy crap, MakerGear Technical Support is top notch.

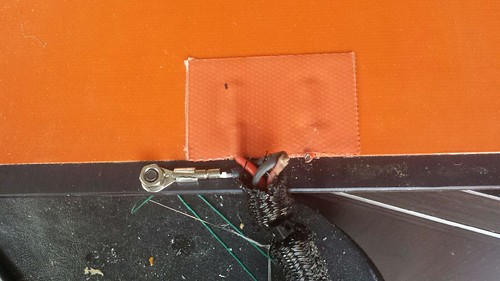

- Heated Bed Issues

A wire to our heated bed snapped. This part was under warranty and MakerGear promptly sent me a new one. In the meantime, we printed on a cold bed with painter’s tape.Perk: I learned to appreciate printing on painters tape. I actually ended up loving that I don’t have to wait for the print bed to heat up to begin and wait for it to cool to pull off prints. I can see occasions in the future where my first choice will be to print on a cool bed.

- End of Life Extruder Drive

In troubleshooting a filament drive issue (see below), we noticed the hot end was loose in the extruder drive. I learned from Technical Support that “Generally the v3b extruder system is expected to last about 6 months of ‘normal’ usage. This could be accelerated with more abrasive filaments or just heavy usage.”Perk: Validation– I’m a heavy user! I’m a heavy user, everyone! : )

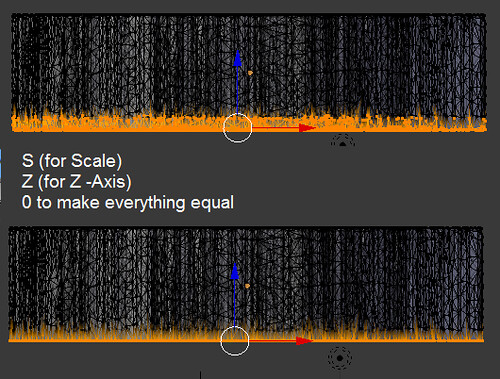

- Filament Motor Issues

My filament motor was clicking and jamming when I did a Retract -100 in Simplify3d (even when the filament drive and hot end were off– the gear itself would stop spinning). Since I’ve done my fair share of technical support with software, I tried to gather up as much information as I could about the issue, even getting the behavior on video. MakerGear send me a new Filament Motor and I’m shipping the old one back to them for some diagnostics.Perk – I’ve built confidence and got to know my printer better by taking apart the filament drive.

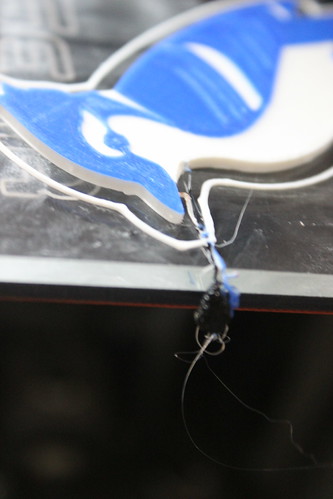

- Broken Cooling Blade

And this one was me. Totally me. I dropped some filament into the running cooling fan and snapped a blade.Perk – The Cooling Fan still ran fine sans one blade… and the replacement only cost 7.50.

Now that was a lot of issues in this past week. Well, would you believe it– we still managed to keep up our Craft Show production!

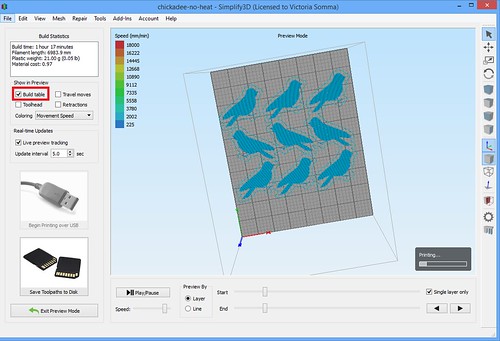

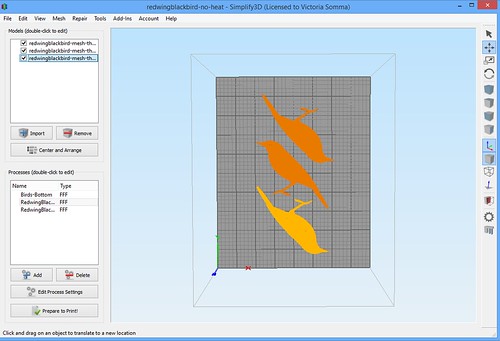

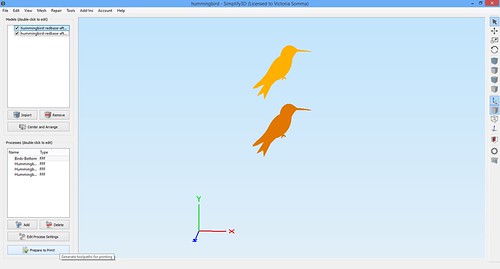

New Finch and Cardinal

I revamped my finch design to make the wing detail simpler so he matched the look and feel of the other birds, particularly the Oriole and the Blue Jay.

And after five iterations, I finally got a dang cardinal I like. The trick was adding in orange for his beak and feet. Subtle, but made a difference.

Fireflies!

I also got a Eastern Common Firefly design I’m happy with. His butt is in GlowFill, so it actually glows.

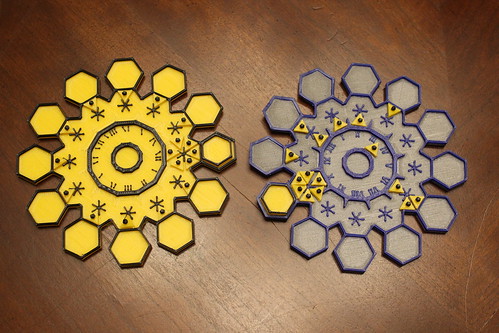

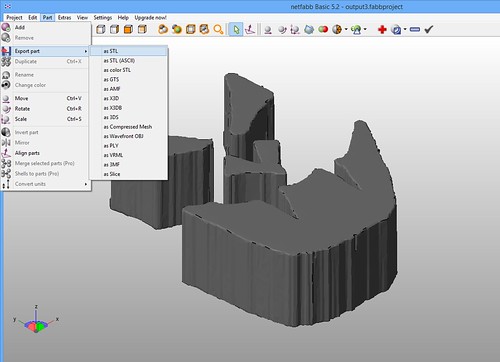

Dyson Spheres

Ryan is creating a table top game he is calling “Dyson Spheres”. He modelled the board and the pieces in OpenSCAD and we printed out a few copies for play testing. The printing part has proven to be a lot easier than the play testing. Play testing is hard when you have a 2 year old and a 4 year old constantly trying to steal your pieces.

Atom Pendants Back on the Table

Previously I had fretted about adding the lovely Creative Commons Science-themed pendant to our Craft Show inventory because the hole was so small. Turns out the hole is perfect for 9mm rings. Thank you Michaels…and thank you Creative Commons.

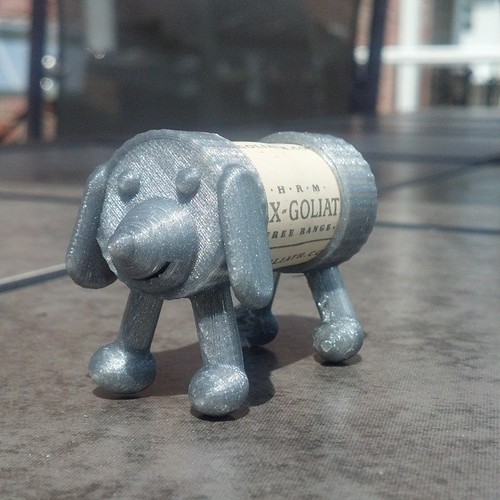

Cork Puppies? Cork Kitties?

Last Friday night, I was looking at an overflowing bowl of wine corks my Mom had collected. I tried to brainstorm some projects for them– like Cork Snowflakes. Sidebar– it’s hard to experiment with corks when a 2 year old and a 4 year old are constantly trying to steal your corks. : )

I thought about making the corks into cats. Cork Kitties– the alliteration alone makes me want to model it. Turns out someone had already done something similar. Designer EHM made a Cork Puppy on Thingiverse. We did a test print and my Mom was instantly in love.

The design is licensed Creative Commons for Non-Commercial Use. I wrote the designer to see if I could license the design or split profits for the Craft Show. I hadn’t heard back yet, so I may have to go back to my original plan. Cork Kitties. : )

Logo

Been working with my graphics designer sister-in-law for a logo. For the first time in my life, I picked a logo based on “how will it look as a 3D print?”. Our lead contender would make a mighty fine pendant.

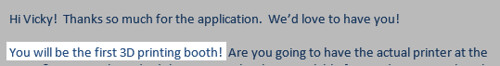

Staging

We have four weeks, but we are already mucking around figuring out how we want to display all this stuff. We happened to find an old metal birdhouse on clearance that our magnet birds stick to. It might be destiny.

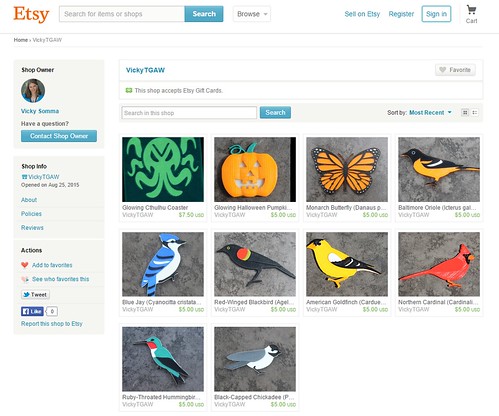

Etsy

And I did manage to post some things to Etsy finally. I won’t be heavily promoting it until October…. after the Craft Show. Nonetheless, my heart does a little pitter-patter when I see how my prints are all starting to come together into a product line.

So yeah. I’ve been busy. : )