The 2025 rendition of 3DPrintopia happened recently. It was our last event with the APGFCU Arena as our home. The wonderful writer and long-time ERRF/3DPrintopia Exhibitor, Denise Bertacci (aka stlDenise) wrote a delightful recap of our last year in Bel Air for Tom’s Hardware.

Category: Uncategorized

Derby Encouragement from Kai Wener

Sagan has gotten lots of touching messages and words of encouragement regarding The Orville 3D Printed Derby Car. This is one of my favorites– from the day of the derby:

Your #TheOrville Derby car looks absolutely AWESOME Sagan! Best of luck in today's race from the kids aboard @TheOrville …Represent for us! 🚀🛸🚘 @KaiWener and @BJTannerTv #FinnFamily #FinnBoys #GoodLuck

— Kai Wener (@KaiWener) June 22, 2018

Happy Anniversary #F3DPCH!

Tonight was the one year anniversary of the Friday 3D Printing Community Hangout! A number of special guests were in the hangout tonight including Heather Womack of #3DPinkMafia fame, Lauren from Abuzz Designs, and even Tessa from SparkyFace5. What a delightful event. I showed up late, but very much enjoyed seeing everyone!

For more details on future Friday Night 3DP Community Hangouts, follow @F3DPCH on Twitter.

Washington Post Highlights the Rockledge Ornament!

I had the honor of 3D Modeling and 3D Printing another ornament to represent the Town of Occoquan for the holidays at the Virginia Executive Mansion.

An article about the ornament appeared in the Prince William section of the Washington Post today. You can read the full article at https://www.washingtonpost.com/local/occoquan-artist-trims-the-governors-tree-with-a-little-festive-3-d-history/2016/12/02/04ebb97c-b80c-11e6-a677-b608fbb3aaf6_story.html

Fun with Gyro Cubes!

I recently uploaded my remix Gyro Cube to Thingiverse! That’s up at http://www.thingiverse.com/thing:1722631 It includes three files:

- A “Print in Place” version where all the spheres print in position and work as soon as you remove support material.

- A “Snap in Place” version where all the spheres print directly on the bed and you snap them into position after printing.

- All the OpenSCAD code for future remixes.

My version is a remix of smorloc’s Big Nippled Parametric Gyro Cube (http://www.thingiverse.com/thing:40760) which in turn is a remix of whosawhatsis’s Parametric Gyro Cube (http://www.thingiverse.com/thing:19304). A remix of a remix!This video hits on a bunch of things:

1) Using Simplify3D’s Mesh-Separate Connected Surfaces to preview and get a feel for the connections of the existing Gyro Cube models.

- My modifications to the Big Nippled Gyro Cube , my thought process behind my new connections, and printing the spheres in place.

- Using Simplify3D’s Cross Section View to determine good stopping points for embedding the spheres within each other and

using Multiple Processes to achieve a five color Gyro Cube on my single extruder machine. - Since my family is completely in love with Pokémon Go, I also go over using Multiple Processes and the Print-in-Place version of in Simplify3D to make a Pokeball Gyro Cube.

- Passing on a tip from TimeFramed from the Big Thick Gyro Cube V2 (http://www.thingiverse.com/thing:165424) and incorporating a vertical lift to my retractions.

Custom GCode Scripts for Embedded Spheres

=====================================

Ending

G91; relative mode

G1 Z100; lift 100mm

Starting

G90; absolute mode

Processes for Embedded Spheres

(From smallest to largest)

===================================

Sphere 1

-One process for the whole thing

Sphere 2

-0 – 40 mms

-Insert Sphere 1

-40mms on

Sphere 3

-0 – 50 mms

-Insert Sphere 2

-50mms on

Sphere 4

-0 – 60 mms

-Insert Sphere 3

-60mms on

Sphere 5

– 0 – 71 mms

– Insert Sphere 4

– 71 mms on

Custom GCode Scripts for Pokémon Go

=====================================

(When starting I add calls to purge the nozzle due to color changes)

Ending

G91; relative mode

G1 Z100; lift 100mm

Starting

G90 ; absolute mode

G92 E0 ; zero extruder

G1 E25 F225 ; purge nozzle

G92 E0 ; zero extruder

Processes for Pokémon Go

=====================================

– 0 – 35mm – White

– 35mm – 45mm – Black

– 45mm – 80mm – Red

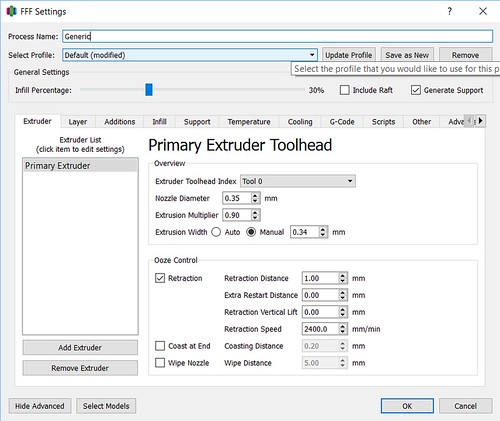

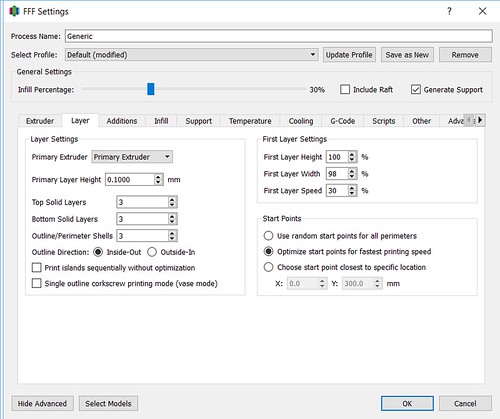

Tour of my Simplify3D Settings – As Of January 2016

Another post inspired by a Twitter conversation!

Here’s a quick tour of my Slicer Settings for the MakerGear M2 (v3b Hot End) for my PLA/PHA.

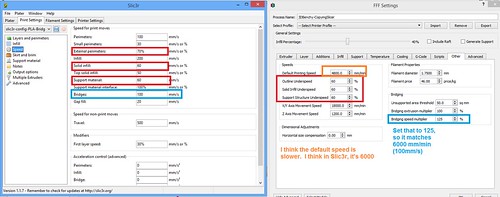

Hat Tip – A lot of my settings, especially my speed settings, all stem from Ed Nisley’s Settings for the Bridge Calibration Tool. His settings are for Slic3r. I did my best interpretation to convert them over when I started using Simplify3D. My notes and screenshots of trying to match things up are on Flickr at: https://www.flickr.com/photos/tgaw/albums/72157656224789835

Okay without further ado.

Nozzle Diameter

0.35 – To match my current nozzle.

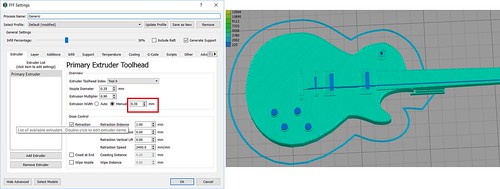

Extrusion Width

Typically– 0.35. I have used the “Auto” which sets to 0.42 without issue.

Exception– In the case of super thin details I have decreased that to 0.34 so the printer will pick them up. An example is a Les Paul Slash Guitar I was working on. At 0.35, the strings were not picked up, but when I changed the Extrusion Width to 0.34, it picked them up.

Ooze Control

I have not actually played with those settings a lot. They are likely the stock settings from the MakerGear M2 profile for Simplify3D

Primary Layer Height

I print anywhere from 0.10 to 0.25. It depends on the projects. Stuff like Cork Kitties, I’m good at 0.25. My multi-colored birds, I want the details to be as close to the base bird as I can, so I print those at 0.10.

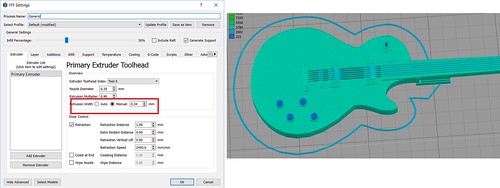

Top Solid Layers

I usually keep this at 3.

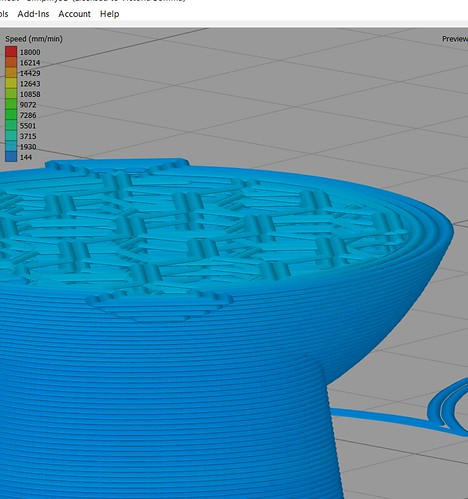

Exception- If I’m working on a piece where the primary focus of it is going to be on the very top (such as the Les Paul Slash Guitar), I will up the Top Solid Layers, sometimes up to 10 (so 1mm at 0.10mm layer heights). This is particularly important if I am using low or no infill. An overkill example is below, but you can see how the combination of Top Solid Layers and Infill can have an impact.

Bottom Solid Layers

I usually keep this at 3

Exception – I have Standing Cancer Ribbon that I print with extra solid layers at the bottom in an attempt to weigh the legs down more. (I have no evidence that is necessary- it worked the first time so I kept doing it)

Outline Perimeter Shells

Typically I keep this at 3.

Exception – If I’m doing something with bronzeFill that I expect to do extra sanding, I up this to 5. (Hat Tip, Barnacles Nerdgasm)

Exception – If I have engraved Text at the top of my piece, I will sometimes lower the perimeters to 1 as it makes the text more crisp.

Outline Direction

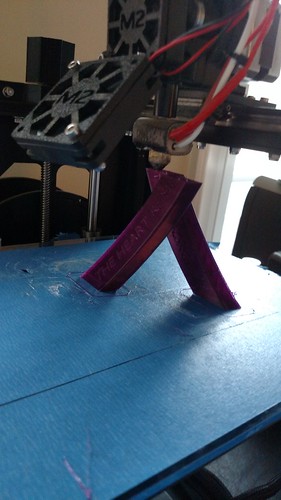

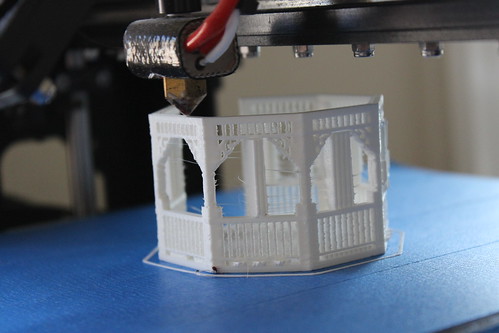

Inside-Out – I believe this is the default and it helps with overhangs quite a bit. Because it is starting from the inside, you are more likely to have something underneath it from the layer before to support your new layer. So if it prints inside out, it has a good base before getting to the overhang areas. An example is the 3D Hubs Marvin. If you look at the curvature on his butt. If the first perimeter is printing on the inside, there is definitely something there for it to print on top of.

First Layer Height

With right now how my bed and Z-End Stop is setup, I am having great results with a First Layer Height of 0.10. So this percentage is all determined by my Primary Layer Height.

If I’m printing at 0.10 layers, I use 100%

If I’m printing at 0.20 layers, I use 50%

If I’m printing at 0.25 layers, I use 40%, etc.

First Layer Width

Converting Ed Nisley’s Settings from Slic3r, I came up with 93%.

First Layer Speed

This I keep at 30%. I believe that also stemmed from my Slic3r settings.

Start Points

I use Optimize Starting Points for Fastest Printing Speed. This I stumbled upon trying to get rid of some pimples and oozing on some prints. Once I checked this, my problems disappeared. I suspect this could also be addressed with Retraction Settings but right now, this solution is working great for me.

A photo posted by Vicky Somma (@vickytgaw) on

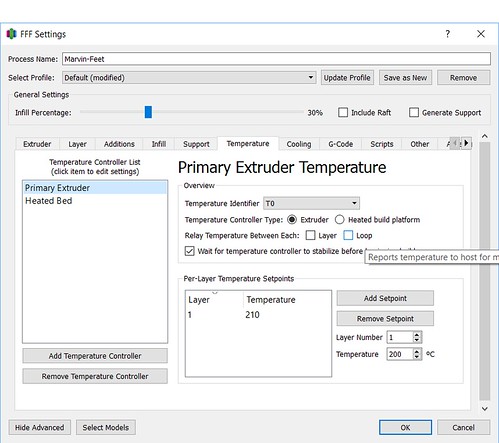

Primary Extruder

I use 210 for all my ColorFabb PLA/PHA

For my MakerGear PLA (my White, Orange, Silver, Black, Purple), I will often use 215, but will sometimes drop that down to 210 if I’m doing something with a lot of overhangs.

BronzeFill and GlowFill I typically use 210.

Heated Bed

Get this. I’m in love with printing on a cool bed on painters tape (And I have that luxury with the materials I have been working with). So I have that set to 0.

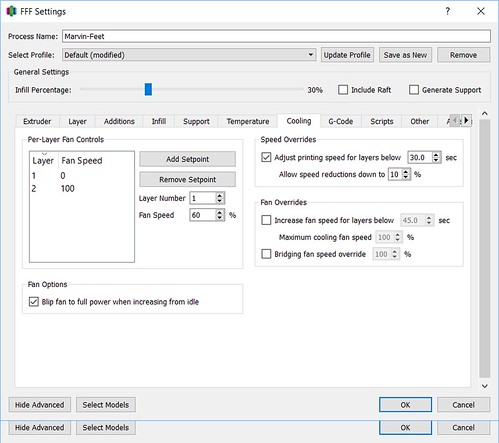

Speed Overrides

When I was trying to print 3D Benchy, I noted my results in Simplify3D were not as good as my original prints in Slic3r. I went back and reviewed my Slic3r settings and found a whole section I had skipped over because it looked waaay too intimidating.

Now if I am working with a print with lots of overhangs or small details that will need to cool, I will check “Adjust printing speed for layers below” and I set it to 30 (down from 60). I also give it way more leeway with how slow it can go– I set that to 10%.

I often will uncheck this setting if my printer is really flat and straight forward and really doesn’t need extra time to cool before starting the next layer.

For my printing speeds, it is all my calculations of my old Slic3r settings that I based off of Ed Nisley.

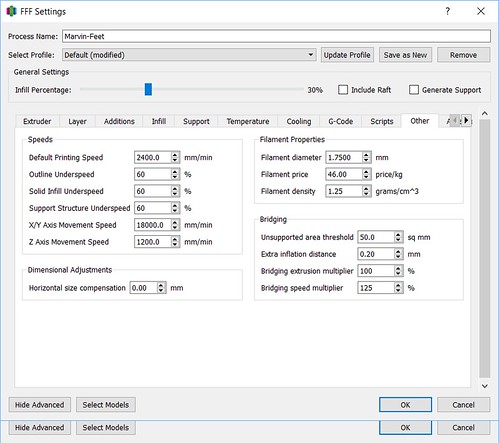

Default Printing Speed

4800.00 mm/min (which is 80mm/sec)

Bridge Speed Multiplier

I set to 125% to get it up to 100mm/sec.

Conclusion

And there you have it. A tour of my settings. Areas where I think there can be some improvement– I do have a model that is subject to some stringing, so I may want to play with lower printing speeds.

And it is possible I can improve my retraction settings, but like I said above, with my Starting Point settings, that issue has not been bothering me.

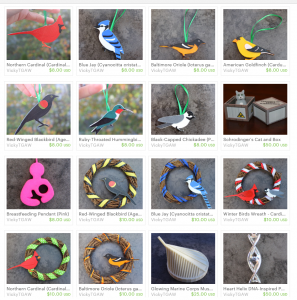

Marathon Etsy-ing

Phew. Did some catch up on my Etsy site and got a bunch more products listed this week including:

- Bird Christmas Ornaments and Wreaths – for the Nature Lovers on your Christmas list!

- The National Museum of the Marine Corp – a special model for a show I did in Quantico, Virginia. The model glows in the dark and can be lit within by LED

- Library of Congress Ornament– which scored me a trip to the White House.

- Schrodinger’s Cat and Box – It has been a surprise sleeper at the craft shows, so I decided it was Etsy-worthy. 🙂

- Breastfeeding Pendants – where my 3D Printing journey began!

- Heart Helix Pendants – My current favorite necklace– hearts twisted into a double helix.

Enjoy!

TGAW 3D on Facebook

TGAW 3D now has Facebook page.

Don’t worry- I’ll still be doing more detailed updates here on the blog. : )