There are a lot of options for both 3D Printers and 3D Modeling software out there. Finding the right tool for you, your mindset, and your processes can make a vast difference in your experience. Our guest tonight, Bearded Printer, learned that firsthand! His early 3D Printing experiences were a bit bumpy and frustrating. In fact, his very first print started with the nozzle digging into the bed! But with time and research, he was able to find the tools and the features, like a filament run out sensor, that changed his experience dramatically.

Today, he is a proven 3D Designer. He’s won prizes in the Weekly Leagues from Thangs. He has been highlighted in a PezLiz’s Meet Designer episode and was profiled by All3DP. Between Printables, Thangs, and Maker World, his 3D Models and printer profiles have over 435,000 downloads– that’s closing in on half a million downloads!

He has a special fancy for floppy, articulated designs including a “Floppy Floppy Disk”. But he also does prints for the home, both functional and aesthetic like lovely such as a colorful Lighthouse Lamps. And he isn’t afraid to go large, demonstrated for by the live-size Dummy13 he printed and brought to 3DPrintopia 2025.

Tonight we welcome, Bearded Printer! https://www.beardedprinter.com/

Earlier this year, I made my first Pull Request in GitHub for PrusaSlicer! I am simultaneously excited…and nervous.

Earlier, I had blogged about how I made custom infills in the PrusaSlicer source code. Those custom infills worked very similarly where I defined points and had the slicer repeat those points over and over.

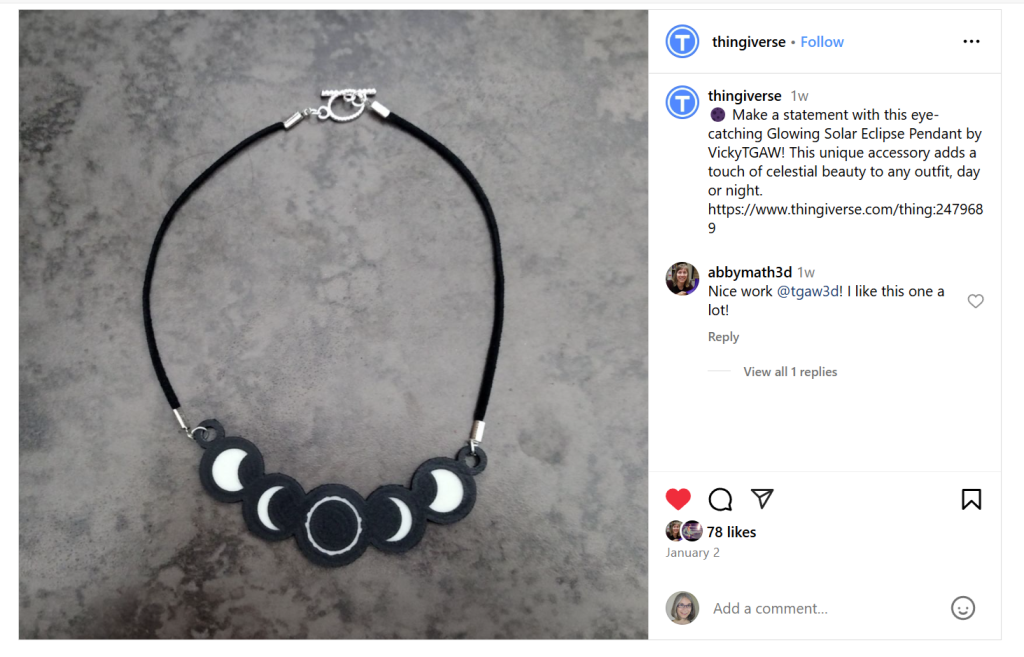

It was brought to my attention that Cura had a great Zig Zag feature that allowed people to define custom angles for that infill which resulted in some lovely patterns when you turn off perimeters and walls. It’s a popular technique with 3D Printed shoes. This Instagram post is a great example of the Cura ZigZag infill in action:

The community had started PrusaSlicer towards that journey of the powerful Zig Zag infill, but it lacked the ability to define those angles. It took a lot more digging than my other infills, but I was able to add a new “Export Mode” setting and duplicate the feature in PrusaSlicer.

I did an awful lot of testing of the feature, including regression testing other infill types to make sure they weren’t impacted by the change. One of my favorite tests, however, was this “Daisy Infill Bowl” by 3D Print Bunny. She designed this with exposed infill specifically in mind. Using my new PrusaSlicer setting, I did infill angles of “90,0,90,0,90,0,270,180,270,180,270,180”. The result was stunning, particularly in this Eryone3D Teal & Purple.

You can learn more about the code changes and the testing on the Pull Request in GitHub at Expansion of the Zig Zag Infill to Allow Control of Angles for Patterning like Cura by VickyTGAW · Pull Request #14073 · prusa3d/PrusaSlicer